Looking for a reliable French fries production line? Foodline designs and manufactures complete fries processing lines suitable for different markets, production capacities and investment levels. Our line covers the entire process, from raw potatoes to perfectly cut, blanched, fried, and frozen fries.

Request for a free quotation, whether you’re a small snack factory or a large-scale food processing plant. Tel/WhatsApp/WeChat: +86 17837195753.

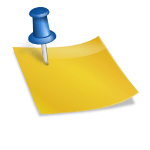

Foodline French Fries Production Line

Complete French Fries Processing Flow

Potato lifting → washing & peeling → cutting → bubble washing → blanching → vibration dewatering → air drying → frying → vibration deoiling → cooling → freezing → packaging

- Fresh potatoes are lifted and fed into the production line evenly.

- Potatoes are thoroughly washed and peeled to remove soil, impurities, and skins.

- Peeled potatoes are cut into uniform strips of the required size.

- The cut potato strips are cleaned to remove excess surface starch and prevent sticking and discoloration.

- Potato strips are blanched to inactivate enzymes and improve color and texture.

- Surface water is removed by vibration.

- Moisture is further reduced by air blowing.

- Potato strips are continuously fried at controlled temperature.

- Excess oil is removed through vibration to reduce oil content.

- Fried fries are cooled to stabilize the product before freezing.

- Fries are rapidly frozen to maintain freshness, shape, and quality.

- Fries are automatically weighed and packed into bags.

The French fries processing flow is not one-size-fits-all. We can design and customize the most suitable processing line for your production.

Contact us to customize your fries line workflow! WhatsApp/Tel/WeChat: +86 17837195753

Main Machines in French Fries Production Line

Potato Elevator → Washing & Peeling Machine → Cutting Machine → Bubble Washing Machine → Blanching Machine → Vibration Dewatering Machine → Air Drying Machine → Frying Machine → Vibration De-oiling Machine → Cooling Conveyor → Quick Freezer → Packaging Machine

Potato elevator

Function: Transfers raw potatoes from ground level to the next processing stage.

Features: Smooth conveying, gentle product handling.

Parameters:

- Overall Dimensions: 2500*600*1650mm

- Power: 0.55kw /380v/ 50Hz

- Material: 304 Stainless Steel

Potato washing and peeling machine

Function: Cleans potatoes and removes skins before cutting.

Feature: High peeling efficiency, low potato loss, easy to clean.

Parameters:

- Overall Dimensions: 1450*825*1238mm

- Roller Brush Length: 1200mm

- Power: 1.5kw/380v/50Hz

- Frame: 304 Stainless Steel

Function: Cuts peeled potatoes into uniform French fry strips.

Feature: Adjustable cutting sizes, stable cutting performance.

Parameters:

- Overall Dimensions: 1070*560*900mm

- Power: 1.5kw/380v/50Hz

- Fries Size: 7-10mm

- Capacity: 400-500kg/h

Function: Separates and washes away free starch released during cutting.

Feature: Gentle washing, efficient starch reduction.

Parameters:

- Overall Dimensions: 2500*850*2020mm

- Power: 4.45kw/380v/50Hz

- Effective Width of Conveyor Belt: 600mm

Function: Blanches potato strips to control enzyme activity.

Feature: Accurate temperature control, continuous operation.

Parameters:

- Overall Dimensions: 3500*850*1450mm

- Total Power: 51kw/380v/50hz

- Effective Width of Conveyor Belt: 600mm

- Drive motor: Variable-frequency speed control motor

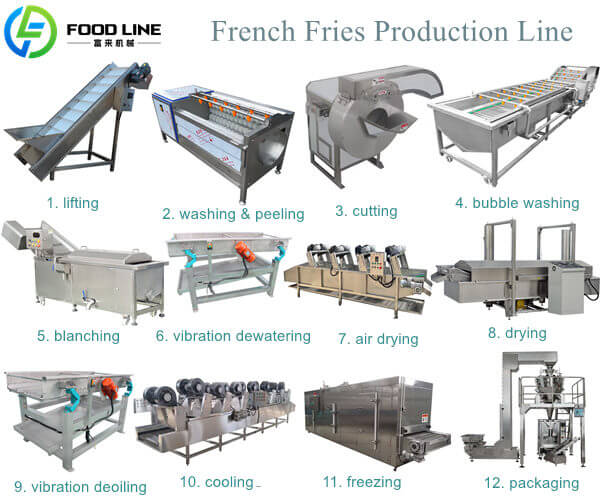

Vibration dewatering machine

Function: Eliminates residual surface moisture after thermal processing.

Feature: Vibration-based water removal, compact structure.

Parameters:

- Overall Dimensions: 2000*800*980mm

- Power: 0.16kw/380v/50hz

- Hole spacing: 2-3mm

Function: Reduces surface humidity to prepare products for efficient frying.

Feature: High-speed air circulation, low oil uptake.

Parameters:

- Overall Dimensions: 3000*700*1650mm

- Total Power: 3kw/380v/50Hz

- Effective Width of Conveyor Belt: 600mm

Function: Fries potato strips to form texture and flavor.

Feature: Automatic temperature control, continuous frying system.

Parameters:

- Overall Dimensions: 3500*950*1850mm

- Total Power: 57.55kw / 380v / 50Hz

- Effective Width of Conveyor Belt: 600mm

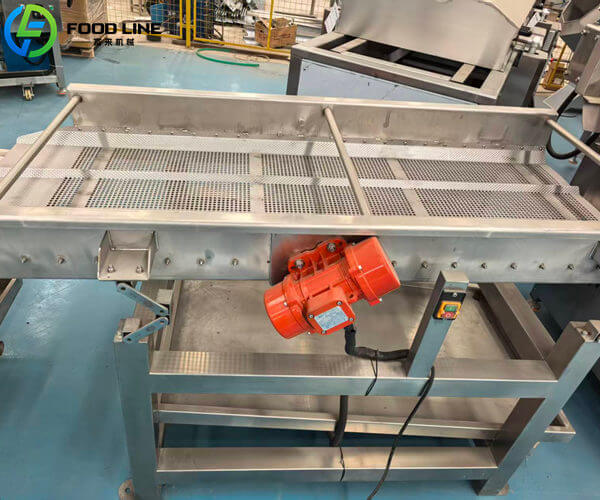

Vibration deoiling machine

Function: Separates excess frying oil from the product surface.

Feature: Vibration-assisted oil removal, improves final product quality.

Parameters:

- Overall Dimensions: 2000*800*980mm

- Power: 0.16kw/380v/50hz

- Hole spacing: 2-3mm

Function: Lowers product temperature, ensure stable structure before freezing

Feature: Smooth conveying, prevents adhesion between fries.

Parameters:

- Overall Dimensions: 3000*700*1650mm

- Total Power: 3kw / 380v / 50Hz

- Effective Width of Conveyor Belt: 600mm

Function: Rapidly freezes fries to lock in its quality.

Feature: Individual freezing, fast freezing speed, minimal product deformation.

Parameters:

- Overall Dimensions: 6600*4000*3300mm

- Freezing Time: 10-80 min

- Inlet Temperature: ≤ +15°C

- Outlet Core Temperature: Below -18°C

The equipment in our French fries production line is flexible. You can customize the machines according to your capacity needs and plant area, and we welcome such customization!

Design Your French Fries Line Machine Today! Tel/WhatsApp/WeChat: +86 17837195753

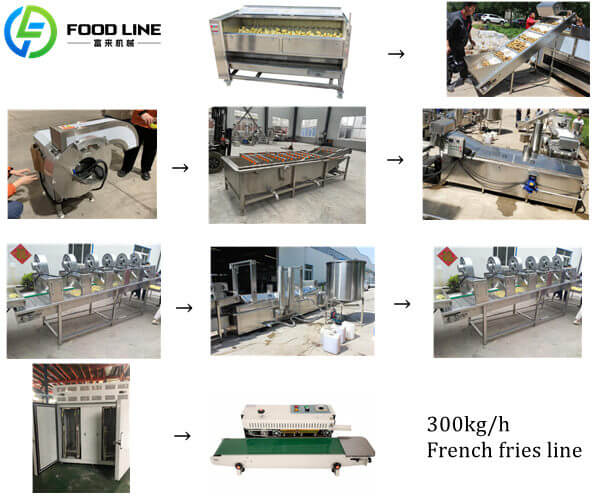

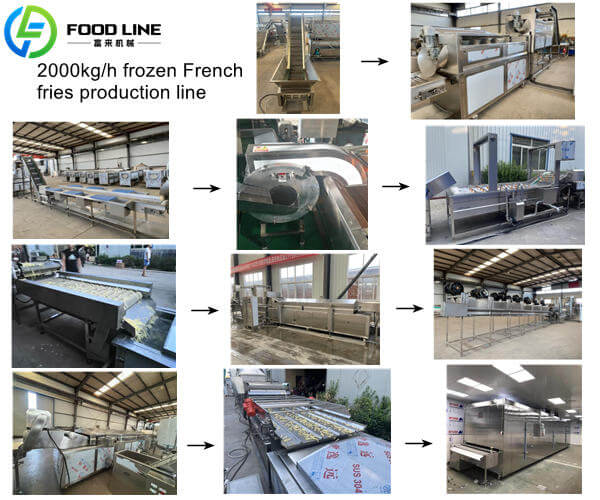

Production Capacity Options

Foodline designs French fries processing line to match your exact capacity needs, from pilot-scale projects to full industrial production.

Our capacity options range from

30kg/h, 50kg/h, 70kg/h, 100kg/h, 200kg/h, 300kg/h, 500kg/h, 1000kg/h, 2000kg/h, etc.

Our engineering team builds each fries line according to your factory space, labor plan, and target market.

We offer semi-automatic lines for flexible startups and fully automatic lines for high-volume, continuous production. We also offer fresh fries lines and frozen fries lines. Whether you plan to expand your current operation or launch a new fries factory, we can provide scalable and reliable production line packages.

Different Equipment Configurations for French Fries Production Lines

Tailored Solutions Start with Your Free Quote!

Key Features of Our French Fries Making Line

The entire process is automated with PLC control system, realizing intelligent operation and reducing manual intervention.

Food-contact parts are made of food-grade stainless steel that is corrosion-resistant, high-temperature resistant, complying with global food safety standards.

Each process (washing, cutting, blanching, frying, etc.) is independently designed, allowing for flexible combination and expansion based on production needs and factory space.

Advanced heat recovery technology and high-efficiency energy-saving motor are used, and wastewater and waste oil treatment meet environmental emission standards.

An intelligent monitoring system provides real-time temperature, humidity, and production capacity monitoring, and automatically alerts for abnormal conditions.

Applications

- Frozen French fries processing plants

- Fast food chain supply factories

- Snack food manufacturing lines

- Supermarket private label production

- Central kitchens and catering facilities

Our French fries production line is widely applicable to various food processing enterprises, and adapts to different production scales and product positioning.

Foodline Machinery – Supplier for Complete Frying Equipment & Processing Lines

Foodline develops, manufactures, and supplies a full range of frying equipment and processing lines for the snack and frozen food industry. We focus on integrated production lines, covering the entire process from raw material handling to finished product packaging.

In addition to French fries production line, Foodline also offers:

- Potato chips processing line

- Banana chips production line

- Customized frying lines for various fried snacks and food products

We design each processing line to match your product type, required capacity, and factory conditions.

Get a Free Solution Now

If you are planning to build or upgrade a French fries production line, Foodline is ready to help.

Contact us to get a competitive quotation.

Tel/WhatsApp/WeChat: +86 17837195753

Email: admin@foodlineproduct.com

You can also submit your inquiry through the form below, and our product expert will contact you shortly.