Great news! Foodline has successfully delivered its vegetable bubble washer to a client in the Netherlands. If you’re looking for an efficient and reliable food cleaning solution, contact us now for your exclusive quote. 📞 Phone/WhatsApp/WeChat: +86 17837195753.

Click here to get your business started!

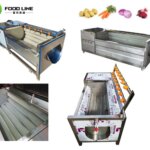

Vegetable Bubble Washer Introduction: Efficient Cleaning for Food Processing

Our bubble cleaning machine for the food industry achieves high-efficiency and gentle cleaning for various ingredients by combining physical bubble agitation with circulating water flow. Key features include:

- Suitable for cleaning leafy vegetables, root vegetables, fruits, and seafood. It excels at removing surface dirt, pesticide residues, and fine impurities.

- The bubble agitation technology replaces traditional mechanical friction, reducing ingredient damage and preserving freshness and appearance.

- The circulating filtration system minimizes water consumption while improving cleaning efficiency, meeting the demands of large-scale processing.

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

Working Case – Communication on Customer Needs

The customer, Jan Smit residing in the Netherlands, operates a fresh-cut vegetable processing business, supplying pre-washed vegetables to local supermarkets and catering chains. As his business grew, Jan faced challenges: low efficiency, high labor costs, and inconsistent cleaning results. Leafy greens often retained soil, and root vegetables had stubborn dirt, leading to increased customer returns and squeezed profits.

Foodline’s sales manager initiated in-depth communication with Jan via WhatsApp:

– Needs identification. Jan highlighted the the need for a machine for cleaning both leafy greens and root vegetables, prioritizing “thorough cleaning, fast speed, and simple operation.” He also asked how the machine could fit into his existing production line.

– Information sharing. The sales manager sent real photos of the vegetable bubble washer and cleaning videos, and also explained how the machine adjusts water flow intensity for different ingredients.

– Parameter confirmation. Considering Jan’s daily processing volume and space constraints, they agreed on key indicators like equipment size and capacity adaptability.

Your Free Quote is One Click Away

Deal & Payment on Vegetable Washing Machine

After watching videos showcasing the fruit and vegetable bubble washing machine’s actual cleaning performance, Jan grew highly intrigued. He focused on two details: whether “bubble agitation could reduce manual sorting” and “how equipment energy consumption would impact costs.” The sales manager elaborated on the benefits: “bubble flow can replace 60% of manual sorting work” and “hourly power consumption is only half that of traditional machines with the same capacity”.

After several days of consideration, Jan confirmed the order and paid the deposit via bank transfer. In the WhatsApp chat, he said that he had compared machines from other suppliers but felt that the bubble technology was far better suited to their specific needs. Additionally, he praised the impressively fast communication, highlighting how the process (from initial inquiry to proposed solution) took merely two days.

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Specifications of Bubble Washing Machine For Vegetable Cleaning

| Model | FL-100 |

| Power | 7.5Kw |

| Voltage | 380v |

| N.W | 800kg |

| Capacity | 2000kg/h |

| Material | SUS304 |

| Dimensions | 6000*1000*1700mm |

Tailored Solutions Start with Your Free Quote!

Business Improvements with Foodline Vegetable Bubble Washing Machinery

Jan’s fresh-cut vegetable business saw remarkable changes with the help of Foodline vegetable bubble washer.

Regarding cleaning efficiency, daily processing capacity increased from 300 kg/hour to 500 kg/hour, with total daily output exceeding 3 tons, meeting new supermarket orders.

In terms of cleaning quality, soil residue on leafy greens dropped from 15% to below 2%, and root vegetables were completely free of surface dirt.

As for cost & profit, manual sorting positions were reduced from 4 to 1 (only for spot checks), saving cost in labor costs. The payback period was just 3 months.

When it comes to customer satisfaction, local supermarkets reported “cleanliness meeting imported standards,” helping jan secure a new quarterly long-term contract. Annual revenue is expected to grow by 30%.

He shared on WhatsApp: “This machine is a smart investment for me this year, as it not only solves cleaning challenges but directly drives business growth.”

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Why Choose Foodline as Your Reliable Partner?

Foodline specializes in the research, development, and manufacturing of food processing equipment. With years of technical expertise and global service experience, Foodline is committed to providing efficient, customized cleaning solutions for clients worldwide. From initial consultation to equipment installation, we focus on real-world customer needs to ensure every machine truly enhances productivity and profitability.

If you, like Jan, want to solve cleaning challenges and boost your business, contact us now. We look forward to customizing the perfect solution for you. Phone/WhatsApp/WeChat: +86 17837195753.