Potato chips stand out as perennial favorites, with consistent demand across households, restaurants, cafes, and retail stores. The semi-automatic potato chip production line has emerged as an ideal solution. This production line combines efficiency, cost-effectiveness, and flexibility, making it suitable for a variety of production settings. Get a free quotation today: WhatsApp/Tel/WeChat: +86 17837195753.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Foodline Potato Chip Production Line for Sale

The semi-automatic processing system for potato chips is different from large-scale fully automated production lines that require huge capital investment, large factory space and a large operation team. It aims to balance efficiency, flexibility, and affordability. Typically, the semi-automatic potato chips line offers production capacities of 30kg/h, 50kg/h, 70kg/h, 80kg/h, etc and is ideal for businesses looking to meet mid-range market demands without over-investing resources. As a leading manufacturer of food processing equipment, Foodline offers turnkey solutions for small-scale production, including complete line setups, stand-alone machines, matching accessories, and complete systems tailored to specific customer needs.

Technical Parameters of Potato Chips Manufacturing Line Machines (30kg/h)

| Name | Power | Capacity | Dimension | Weight |

| Washing and peeling | 1.5kw 380V-3 or 220V-3 | 600kg/h | 1600*850*800mm | 180kg |

| Slicing and cutting machine | 1.1kw 380V-3 or 220V-3 | 300kg/h | 950*800*950mm | 110kg |

| Blanching machine | 12kw 380V-3 or 220V-3 | 80-100kg/h | 700*700*950mm | 70kg |

| Dehydration machine | 1.1kw 380V-3 or 220V-3 | 100kg/h | 900*500*850mm | 320kg |

| Frying machine | 12kw 380V-3 or 220V-3 | 30-60kg/h | 700*700*950mm | 80kg |

| Deoiling machine | 1.5kw 380V-3 or 220V-3 | 100kg/h | 900*500*850mm | 320kg |

| Seasoning machine | 1.1kw 380V-3 or 220V-3 | 300kg/h | 1100*800*1300mm | 190kg |

| Packaging machine | 1.1kw 380V-3 or 220V-3 | 30-60kg /h | 600*600*850mm | 120kg |

Contact us today to get a free quota on potato chip production line. Phone/WhatsApp/WeChat: +86 17837195753

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

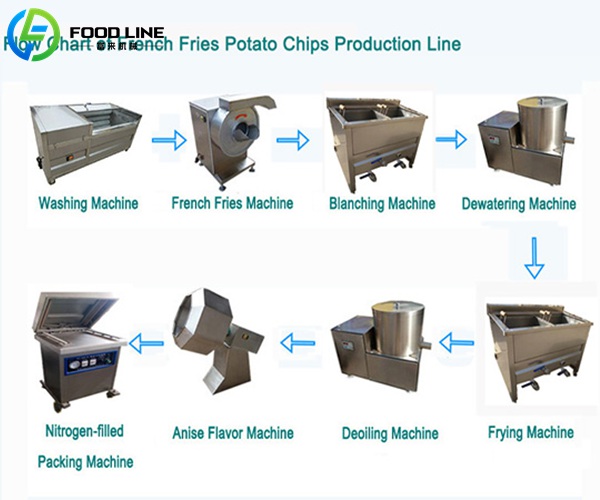

Composition of Our Manufacturing Line for Potato Chips

As shown in the parameter table above, our semi-automatic potato chip line covers eight types of machines. Now let me explain it to you in detail.

1. Brush roller washing and peeling machine

– Key function: To remove dirt, sand, and surface impurities from raw potatoes, and to peel the outer skin (a necessary step for chips, as the skin can affect texture and appearance).

– Working principle: The machine combines high-pressure water jets and rotating abrasive rollers. Raw potatoes are loaded into the hopper and conveyed to the washing chamber, where high-pressure water sprays away surface dirt. Next, the potatoes pass through rotating abrasive rollers that gently scrub off the skin. The peeled potatoes are then rinsed again with clean water to remove peel residues.

2. Slicing and cutting machine

– Key function: To cut peeled potatoes into uniform thin slices (for potato chips).

– Working principle: The machine uses a set of sharp, replaceable blades (made of high-carbon steel for durability) and a conveyor system. Peeled potatoes are fed into the machine’s inlet, where a pusher gently moves them toward the blade assembly. A rotating disc blade cuts the potatoes into thin, even slices.

– Key function: To inactivate enzymes that cause potato slices to turn brown, to partially cook the potato (reducing frying time later), and to remove excess starch (which prevents chips from sticking together during frying).

– Working principle: The machine is a stainless steel tank filled with hot water (or steam-heated water). It submerges potato slices in water at 85-95°C for 1-3 minutes. After blanching, cold water cools the product to stop the cooking process and preserve texture.

– Key function: To remove surface moisture from blanched potato slices. Excess moisture can cause oil splattering during frying, increase oil absorption (leading to greasy products), and reduce frying efficiency.

– Working principle: For smaller lines, a centrifugal dehydrator is common: blanched potatoes are loaded into a rotating drum (speed: 800-1200 rpm) lined with a mesh screen. The drum spins, throwing off surface moisture, which is collected in a drainage tray.

– Key function: To cook potato slices to a crispy, golden texture, using food-grade frying oil (e.g., palm oil, sunflower oil, or canola oil).

– Working principle: The machine is a stainless steel oil tank with a heating system (electric, gas, or steam). The tank is filled with oil, which is heated to the desired temperature. Dehydrated potato slices are fed onto the conveyor belt, which they are fried in hot oil for 2 to 5 minutes. The frying time and temperature are controlled by a digital panel.

– Key function: To remove excess oil from potato chips, reducing fat content (meeting health-conscious consumer demands) and preventing oil leakage in packaging.

– Working principle: Similar to the dehydration machine, the deoiling machine uses centrifugal force. Fried products are loaded into a rotating drum (lined with a heat-resistant mesh) that spins at 1000-1500 rpm for 30-60 seconds. The centrifugal force pulls excess oil away from the product, which is collected in a separate tank for recycling (if still usable) or disposal.

– Key function: To add flavor to potato chips, with options including salt, pepper, cheese powder, barbecue powder, sour cream, or custom flavors (e.g., spicy, garlic, or seaweed).

– Working principle: The machine is a rotating drum with a seasoning sprayer or powder feeder. Fried and deoiled products are added to the drum, which rotates to tumble the product evenly. Seasoning (either liquid or powder) is sprayed or sprinkled onto the product via a controlled feeder—powder seasonings are often mixed with a small amount of oil to ensure adhesion.

– Key function: To package finished potato chips into sealed bags or containers, preserving freshness, extending shelf life, and ensuring product hygiene.

– Working principle: Put the seasoned fries into a plastic bag, with the bag’s open end on the machine’s sealing strip. Close the lid— the machine sucks out air from the bag. Once vacuumed, the strip heats to seal the bag. Release the vacuum, open the lid, and the packaged seasoned fries are ready.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Production Process Flow of Semi-Automatic Potato Chip Production Line

Eight machines in the potato chips line represent eight production processes.

1. Washing and Peeling

This production process begins with the delivery of raw potatoes to the washing and peeling machine. The machine takes in the potatoes (once fed in) and thoroughly cleans and peels them afterward. This step ensures that the raw materials are free from dirt, impurities, and skin, providing a clean base for further processing.

2. Slicing and Cutting

Then, transfer the cleaned and peeled potatoes to the slicing and cutting machine. Here, the machine transforms them into thin slices. The precision of this step is crucial for achieving uniform product size and quality.

3. Blanching

The potato pieces are subjected to hot water treatment in the blanching machine. The blanching process inactivates the oxidizing enzymes, preserving the color and quality of the potatoes and reducing the frying time.

4. Dehydration

Blanched potato pieces are then passed through the dehydrator to remove surface moisture. This step is essential for ensuring even frying and reducing oil absorption, resulting in a crispier and healthier final product.

5. Frying

Dehydrated potato pieces are fried in the frying machine at high temperature. The frying process gives the potato chips their characteristic crispy texture and delicious flavor through a series of chemical and physical reactions.

6. Deoiling

Following frying, the excess oil on the surface of the potato chips is removed using the deoiling machine. This step improves the texture and reduces the fat content of the products.

7. Seasoning

The deoiled potato chips are then transferred to the seasoning machine, where they are coated with the desired seasonings. This step adds flavor and variety to the products, making them more appealing to consumers.

8. Packaging

Finally, the seasoned potato chips are packaged using the packaging machine. The packaging protects the products from external factors and ensures their freshness and quality during storage and transportation.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Core Features of Semi-Automatic Processing Line of Potato Chips

Our full potato chip production line addresses the unique needs of SMEs, startups, and local food businesses. Its design prioritizes usability, cost-efficiency, and adaptability.

1. Moderate, Scalable Production Capacity

With an output range of 30–300 kg per hour, this chips making line aligns perfectly with the demands of local markets, independent retailers, and catering services. Our semi-automatic systems support seamless growth: clients can begin with a 30 kg/h configuration and incrementally upgrade components.

2. Semi-Automatic Operation: Efficiency Meeting Precision

“Semi-automatic” signifies automation of core processes (washing, peeling, slicing, frying) via specialized machinery, with human involvement limited to material loading, parameter monitoring, and inter-machine transfers. This hybrid approach delivers dual advantages: it slashes labor costs compared to fully manual operations (which suffer from inconsistency and worker fatigue) while granting operators granular control over product quality.

3. Compact, Space-Maximizing Design

The processing line features a modular layout, enabling linear or L-shaped configurations that fit effortlessly into compact factories, workshops, or even restaurant back-of-house areas. The floor area of the semi-auto chips production line is much smaller than that of the fully automatic system.

4. Food-Grade Materials for Regulatory Compliance & Safety

Every part of the line—from machine frames to conveyor belts and cutting blades—uses 304 stainless steel in its construction, a globally certified food-contact material compliant with FDA (U.S.), EU Regulation 10/2011, and GB 4806 (China) standards. Renowned for corrosion resistance, ease of cleaning, and non-leaching properties, this material ensures strict adherence to food safety regulations across North America, Europe, Asia, and Africa.

5. Low Energy & Water Consumption: Cost-Effective Sustainability

Catering to the budget constraints of small businesses, the semi-auto chips line prioritizes resource efficiency. The wash/peel unit employs a recirculating water system that filters and reuses up to 70% of water, drastically reducing waste and utility costs. The frying machine’s thermostatic control maintains consistent oil temperatures without excessive energy use.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Application Scenarios of Small-Scale Potato Chip Production Line

The semi-automatic potato chips processing line adapts well to diverse businesses. Below are five practical uses:

1. Small-Scale Food Processing Factories

Local snack makers (SMEs) rely on these lines to craft packaged chips or fries for neighborhood stores, supermarkets, or gas stations. Example: A rural factory with access to cheap, fresh potatoes can output 100 kg of chips daily—enough to supply 50–100 nearby shops. Its compact design fits in a small industrial unit, slashing rent costs.

2. Restaurant and Catering Chains

Large restaurant chains (e.g., burger joints, pizzerias) or catering companies often require a steady supply of fresh fries. A semi-automatic line allows installation in a central kitchen to produce fries for multiple restaurant locations. Benefits? Uniform quality and lower costs—fresh fries are cheaper to make and taste better than frozen ones.

3. Startup and Entrepreneurial Ventures

New entrepreneurs use these low-cost lines to test creative ideas. Think: “healthy” chips (low-fat, organic, or turmeric-infused) sold online or at farmers’ markets. The small upfront investment lets them experiment without heavy debt, while the flexible equipment supports quick flavor or packaging changes.

4. Farm-Based Processing Units

Potato farms often face the challenge of waste: potatoes that are too small, misshapen, or blemished won’t sell fresh but are perfect for processing into fries or chips. A farm can install a 30-100kg/h line to process these “seconds” into value-added products, increasing profit margins.

5. Retail and Convenience Store In-Store Production

Some large retail chains or convenience stores offer freshly made snacks to attract customers. A small 50kg/h line allows installation in the store’s backroom, allowing staff to produce chips on-site and sell them hot or packaged. This “freshly made” appeal can increase foot traffic and sales — customers are often willing to pay a premium for products made in front of them.

Frequently Asked Questions (FAQs)

Q1: What is the difference between a semi-automatic and a fully automatic production line?

A semi-automatic potato chip production line requires manual intervention for tasks like loading raw materials, transferring products between machines, and monitoring parameters. A fully automatic line, in contrast, features full integration—products move from one machine to the next without manual help, and a central computer controls the entire process. Fully automatic lines have higher production capacities but are more expensive, require more space, and are less flexible. Semi-automatic lines are better for small businesses that need moderate capacity, flexibility, and lower costs.

Q2: Can the potato chip production line produce both French fries and potato chips?

Yes! The line has a versatile design—by changing the blades on the slicing/cutting machine and adjusting parameters (e.g., blanching time, frying temperature), you can switch between producing fries and chips in 10-15 minutes. We provide multiple blade sets with each line (one for slicing, one for strip cutting) to facilitate this changeover.

Q3: What type of potatoes are best for the potato chip production line?

Starchy potatoes (e.g., Russet, Idaho) are ideal for French fries, as they have a high starch content and low moisture, leading to crispy fries. Waxy potatoes (e.g., Yukon Gold, Red Bliss) are better for potato chips, as they have a lower starch content and hold their shape well during slicing and frying. The line can process all potato varieties, but we recommend testing different varieties to find the best fit for your target product.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Choose Foodline as Your Partner

Foodline is a trusted manufacturer and global supplier of food processing machinery. Specializing in the design, manufacture, and export of high-performance food equipment, Foodline caters to food producers, commercial kitchens, and industrial factories worldwide. Foodline’s dedication to customer satisfaction extends beyond product quality to include excellent communication and after-sales support. We welcome visitors to their factory to witness the machines in action, discuss projects face-to-face, and understand why customers in over 50 countries trust Foodline. Whether supporting startups or large-scale food producers, Henan Foodline Machinery dedicates itself to providing the right solutions to boost productivity and profitability. Phone/WhatsApp/WeChat: +86 17837195753