An automatic encrusting machine automate the process of forming and filling (or “encrusting”) food products. This high-efficiency food processing device efficiently wraps an outer dough or shell around an inner filling to produce uniform, attractive, and high-quality food items, saving time, labor, and production costs. Foodline provides high-quality encrusting equipment and if you want to learn its price and other detail information, contatc now: Phone/WhatsApp/WeChat: +86 17837195753.

Click here to get your business started!

Foodline Multi-Function Encrusting Machine for Sale

Our encrusting and forming machine aims to encapsulate a portion of filling within a layer of dough, creating a sealed, uniform product ready for cooking or freezing. The name “encrusting” comes from the process of forming a “crust” or outer layer around a central core.

This precision food processing system operates through a continuous, automated cycle. It mirrors the actions of a master chef but delivers high speed, accuracy, and uniformity, piece after piece. Each item has consistent size, weight, and filling distribution, which is difficult to achieve manually on a large scale. Common products made by this machine include stuffed pastries, mochi, cookies, meat buns, energy balls, falafel, dumplings, and other filled foods.

Technical Data of Food Encrusting Equipment

| Capacity | 60-99pcs/min |

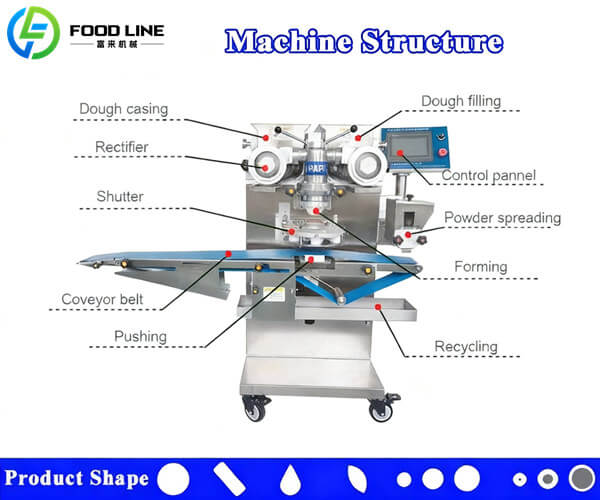

| Product shape | Ball, cone, round strip, side square, terraced, serrate and etc. |

| Product weight | 10-250g |

| casing and filling proportion | 1:9-10:0 |

| Power | 1.75kw |

| Voltage | 220v/50hz |

| Dimension | 1680*860*1300mm |

| Weight | 280KG |

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

How Does It Work? – The Basic Process

The advanced encrusting machine consists of a dough hopper, a filling hopper, a stuffing and forming system, and a cutting mechanism.

1. Feeding. The dough and filling are fed separately into their hoppers.

2. Encrusting. The machine precisely wraps the filling with dough in a uniform ratio, adjusting size and thickness automatically.

3. Shaping: Products can be shaped into balls, rolls, bars, or customized forms using molds or attachments.

4. Discharge. Finished items are conveyed out automatically, ready for baking, frying, or freezing.

Key Features of Food Encruster Machine

Automatic forming and filling – Accurately combines outer dough and inner filling with adjustable ratios.

High production capacity – Capable of producing lots of pieces per hour, depending on size and shape.

Touch screen control – Intuitive interface for setting weight, size, speed, and encrusting thickness.

Versatile molds – Interchangeable forming molds allow for various product shapes and styles.

Hygienic design – Food-grade stainless steel construction ensures easy cleaning and compliance with safety standards.

Stable performance – Precision motor and advanced control system deliver consistent output with minimal downtime.

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Who Should Consider Buying Automatic Encrusting Machine

1. Small & medium food manufacturers: Local bakeries, confectionery factories, frozen food producers, or snack factories that want to automate part of their production line.

2. Bakery & pastry shop owners: Artisan or commercial bakers who make filled pastries, bread, cookies, or traditional desserts.

3. Traditional snack or dessert manufacturers: Producers of ethnic or local delicacies like mochi, tangyuan, mooncakes, maamoul, or sesame balls.

4. Food equipment distributors & dealers: Companies selling food machinery looking to expand their product range.

Key Considerations When Choosing Encrusting Machines

1. Product type. What are you making? The specific shape (round, half-moon, oval) and sealing method will determine the machine type.

2. Production capacity. What is your required output (pieces per hour)?

3. Dough characteristics. Is your dough soft, firm, elastic, laminated, or sticky? The machine must be compatible with your dough’s texture and rheology.

4. Filling characteristics. Is the filling chunky, smooth, pasty, or oily? This will affect the type of filling pump and hopper needed.

5. Ease of cleaning. Machines with a focus on hygiene design will significantly save time and ensure food safety.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

FAQs

Q1: What kind of fillings can the encrusting machine handle?

A: It can process a wide range of fillings, from pastes, minced meat, and jam to chunky or creamy fillings.

Q2: Can I customize product shapes and sizes?

A: Yes. With interchangeable molds and settings, you can produce various shapes and sizes.

Q3: Is the machine easy to clean?

A: Absolutely. All food-contact parts are made from 304 stainless steel and can be easily cleaned thoroughly.

Q4: Does the machine require skilled operators?

A: No. It allows for easy operation with a user-friendly screen interface and simple parameter settings.

Q5: Does the machine support different dough types?

A: Yes. It works with various dough consistencies such as wheat, rice, glutinous, or shortbread dough.

Tailored Solutions Start with Your Free Quote!

Why Foodline?

Foodline specializes in designing and manufacturing reliable food processing equipment to help businesses like yours grow and thrive. Our years of experience in the industry have taught us how to create efficient, durable machines that are easy to operate and maintain. Our product line includes encrusting equipment, donut maker, bagel maker, dumpling maker, and many other food processing solutions.

We firmly believe that quality and service are key to earning customer trust. Whether you are a small bakery or a thriving food producer, we support you with expert advice and reliable after-sales service.

Interested in our encrusting machine or other equipment? Contact us today to get a discount!

WhatsApp/Phone/WeChat: +86 17837195753

Email: admin@foodlineproduct.com