The automatic cashew shelling machine is able to efficiently remove the hard outer shell of raw cashew nuts while preserving the integrity of the kernel. It automates the labor-intensive process of manual shelling, enabling large-scale processing with minimal human intervention. Contact us for a free quote: Phone/WhatsApp/WeChat: +86 17837195753.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

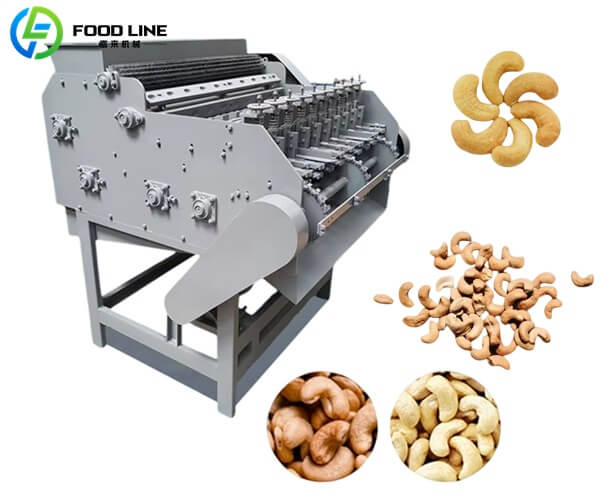

Foodline High-Efficiency Automatic Cashew Shelling Machine for Sale

The automatic cashew nut shelling machine aims for efficient removal of cashew nuts’ hard outer shells. It replaces labor-intensive, slow manual shelling with pre-programmed automated operations, handling various nut sizes via adjustable settings and requiring minimal human intervention. This machine can connect raw shelled nuts to subsequent processing stages, ensuring kernels are freed quickly and undamaged to maintain quality and market value.

The central function of automatic cashew shell removing machines is consistent, efficient, low-waste separation of cashew kernels from shells, relying on three seamless sub-functions:

- Feeding: An automated system delivers raw nuts to the shelling chamber at a steady rate, preventing overload and ensuring proper positioning.

- Shell Breaking: Specialized mechanisms apply calibrated force to crack shells without damaging kernels, adapting to shell thickness variations.

- Kernel-Shell Separation: Air blowers, vibrating screens, or gravity separators separate shells (lighter) from kernels (heavier), eliminating manual sorting and reducing kernel damage risk.

Tailored Solutions Start with Your Free Quote!

Technical Parameters of Cashew Nut Shell Automated Removing Machine

| Capacity | 40-800kg |

| Machine weight | 200-1400kg |

| Voltage | 380V 50HZ |

| Power | 4kw |

| Shelling rate | 95% |

| Broken rate | 5% |

| Unshelling rate | 3% |

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

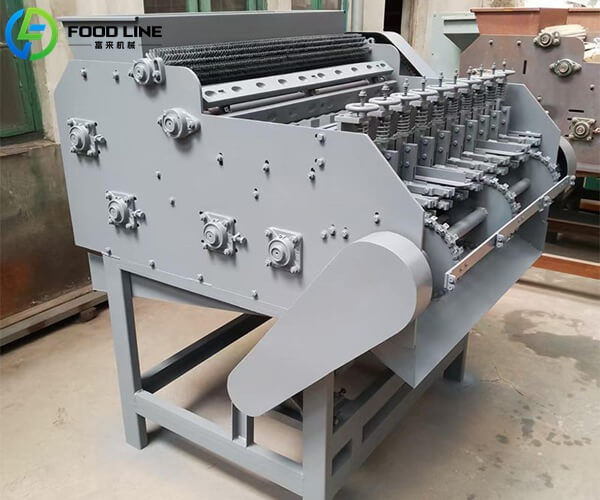

Technical Features of Automatic Cashew Nut Cracking Machine

1. High Productivity

Outperforms manual shelling, processing 40-800 kg of raw nuts per hour. Enables 8-12 hours of continuous operation with automated feeding, avoiding bottlenecks for large orders or seasonal harvests.

2. User-Friendly Operation

Designed for simplicity, with intuitive control panels (for start/stop, speed adjustment, and performance monitoring), 1-2 hours of training required, and easy access to components for quick cleaning or part replacement (under 30 minutes, no specialized tools).

3. High Shelling Rate

Achieves 95% shelling rate, using advanced sensors to detect nut position and thickness for optimal force application. Adjustable settings handle irregular or thick shells, minimizing waste from unprocessed nuts.

4. Low Loss and Breakage Rates

Maintains 3% loss rate (kernels discarded with shells) and <5% breakage rate. Calibrated mechanisms and efficient separation protect kernels, which fetch 20%–30% higher prices when intact.

Your Free Quote is One Click Away

Highlights and Advantages of Industrial Automatic Cashew Shelling Machine

Highlights:

1. High throughput. Processes tons of raw cashews per hour, optimized for industrial demand.

2. Precision engineering. Durable stainless-steel components resist wear from abrasive shell fragments.

3. Smart controls. Digital interfaces regulate speed, pressure, and separation accuracy for consistent results.

4. Low downtime. Quick-release mechanisms simplify cleaning and maintenance.

5. Safety protocols. Emergency stops and enclosed systems prevent operator exposure to moving parts.

Advantages:

1. Boosted productivity. Significantly faster than manual methods, reducing labor costs.

2. High extraction rate. Achieves >95% shell removal efficiency with <5% kernel breakage.

3. Cost efficiency. Lowers waste (unshelled nuts, broken kernels) and energy consumption.

4. Scalable operation. Suitable for small farms, medium processors, and large export facilities.

5. Integration capability. Directly connects to upstream and downstream processes for seamless workflow in cashew processing lines.

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Application Areas of Automatic cashew shelling and cracking machine

1. Cashew Processing Plants

Primary user, handling full processing cycles (cleaning to packaging). Relies on the machine to cut labor intensity and maintain high volumes.

2. Agricultural Cooperatives

Enables quick processing of harvested nuts, letting cooperatives sell kernels directly to boost farmer incomes and local economies.

3. Food Manufacturing Companies

Allows in-house processing of cheaper raw nuts, reducing inventory costs and ensuring freshness. Gives control over kernel quality for snacks, confectionery, and baked goods.

4. Export-Oriented Facilities

Meets strict international standards (high shelling rate, low breakage) for markets like the EU.

Click here to get your business started!

Why Choose Foodline

With years of experience in designing and manufacturing food processing equipment, Foodline prioritizes reliability, performance, and customer-centric solutions—ensuring products align with the exact needs of modern processors. Our automatic cashew shelling machines are sold to many countries and have received wide acclaim. Each machine undergoes rigorous quality testing to meet industry standards, delivering the high shelling rates, low breakage rates, and user-friendly operation outlined above, while also offering flexible customization to fit unique production setups. Foodline’s commitment to quality and service makes it the ideal choice for your cashew processing needs.