With the continuous improvement of consumers’ requirements for food quality and safety, blanching technology has attracted widespread attention due to its unique advantages. Blanching is a process of short-term heat treatment of food raw materials by hot water or steam. This technology can not only effectively control enzyme activity and reduce microbial contamination, but also better maintain the color, texture and nutritional content of food.

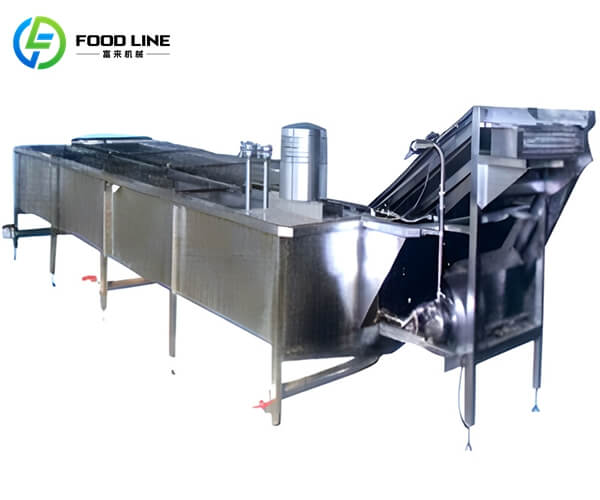

Foodline Blanching Equipment Overview

Foodline energy saving automatic blanching equipment, a piece of food-processing equipment, quickly heats vegetables, fruits, meat, or seafood. The short heat step is called blanching. It removes surface dirt, kills germs, and stops enzyme action. After blanching, the product keeps bright color, good texture, and high nutrition.

The commercial blanching machine uses hot water or steam as a heat medium to heat treat food raw materials under specific temperature and time conditions. Depending on the heat medium, the industrial blancher can be mainly divided into two types: hot water blanching machine and steam blanching machine. Hot water blanching equipment heat the water in the water tank to the set temperature and treat food materials by immersion or spraying. Steam blanching machines use saturated steam to directly act on the surface of the material, and release latent heat through steam condensation to achieve rapid heating.

Specification and Process Flow of Commercial Blancher

| Automatic Blanching Machine | |

| Blanching product | Fruits, vegetables, seafood, packaged food, etc |

| Heating method | Electricity / steam |

| Rated power | Different based on model and products |

| Blanching temperature | Normal temperature-100°C |

| Temperature range | Normal temperature-100°C |

| Temperature precision | ±1°C |

| Blanching time | 1-5mintues adjustable |

| Blanching time control range | Frequency adjustable |

| Mesh belt width | 600mm/800mm/1000mm/1200mm |

The flowing is the process flow of our energy saving automatic blanching equipment

1. Feeding. A belt moves raw product into the machine.

2. Heating. Steam or electric heaters bring water or steam to the set temperature.

3. Blanching. Product travels through the chamber. Water showers or steam surrounds every piece. Time and temperature are fixed by the recipe.

4. Cooling. In the same line, cold water or air quickly cools the product. This stops further heating.

5. Discharge. Product leaves the blancher and moves to freezing, drying, or packaging.

Technical Advantages of Fully Automatic Blanching Machine

1. Energy saver. Steam injection heats water directly. There is no steam loss.

2. High yield. Exact time and temperature protect cell structure. Less product softens or breaks.

3. Gentle rain shower. Water falls by gravity only. Delicate leaves and berries do not tear.

4. Safe and quiet. Closed hood and thick insulation keep noise low. Operators work in normal clothes.

Product Features of Stainless Steel Blanching Equipment

1. Food-grade stainless steel. All parts that touch food in the blancher are SUS304 or better. The surface is easy to clean and meets food safety rules.

2. Precise temperature control. Digital sensors keep water or steam within ±0.5 °C of the set point.

3. Low water use. Cross-flow and steam systems reuse water.

4. Compact layout. Small footprint fits old plants and new lines.

Why Invest in a Blanching Equipment

1. Better quality. Bright color, firm bite, and high vitamin C keep buyers happy.

2. Less waste. Controlled heating means fewer broken pieces. You sell more of what you make.

3. Labor saving. One operator can run the whole line. Manual pots need many workers.

4. Energy saving. Lower steam and water bills pay for the machine within a few months.

5. Food safety. Fast heat kills microbes. Clean-In-Place stops cross-contamination. Your plant passes audits easily.

6. Flexible recipes. Touch screen stores multiple programs. Switch from broccoli to shrimp in minutes.

Where the Energy Saving Automatic Blanching Equipment Can Be Used

1. Frozen vegetable lines. Peas, corn, broccoli, green beans, and carrots are blanched before the freezer.

2. Ready-to-eat salads. Leafy mixes are lightly blanched to keep crisp and safe.

3. Fruit processing. Sliced apples, peaches, and berries keep color before drying or canning.

4. Seafood plants. Shrimp, squid rings, and mussels are cleaned and lightly cooked.

5. Meat and poultry. Chicken strips and beef cubes are blanched before stir-fry kits.

6. Dehydrated foods. Potatoes, herbs, and mushrooms are blanched to set color and shorten drying time.

7. Central kitchens. Large hotels and catering companies use blanchers for fast prep of mixed vegetables.

We Are Real Blanching Equipment Factory

Foodline Machinery is a young yet dynamic manufacturer dedicated to the design, production and global sales of food-processing equipment. It boasts a strong commitment to innovation, quality, and customer satisfaction and caters to a wide range of clients from small businesses to large-scale industrial operations.

Foodline has consistently invested in research and development to stay at the forefront of technological advancements. The company’s state-of-the-art manufacturing facilities are equipped with cutting-edge technology, ensuring that every product meets the highest standards of quality and efficiency.