Are you looking to boost efficiency and quality in your French fries production? Foodline’s semi-automatic French fries production line is your perfect solution. Suitable for food businesses of all sizes, from small factories to large-scale manufacturers, our French fries line creates crispy and delicious fries that your customers will love. WhatsApp/WeChat: +86 17837195753

Click here to get your business started!

Technical Parameters of Foodline French Fries Production Line

| Potato washing and peeling machine | Dimensions: 2600*850*1650mmHair roller length: 1.8 metersPower: 4.55kw /380v/ 50Hz |

| Potato cutting machine | Dimensions: 1070*560*900mmPower: 1.5kw /380v/ 50HzCutting size: 7-10mm |

| Blanching machine | Dimension: 1360*650*700mmWeight: 50kgPower: 15kw / 380v / 50HZMaterial: Stainless Steel |

| Dewatering machine | Power: 0.75KwWeight:400kgDimension:940*560*830mm |

| Frying machine | Power: 21KWWeight:160kgDimension:1380*620*1000 |

| Deoiling machine | Power: 1.1KwWeight: 500kgDimension: 1050*660*930mm |

| Seasoning machine | Power: 0.75kwWeight: 90kgDimension: 1000x800x1380mm |

| Packaging machine | Power: 1KWWeight: 80kgDimension: 540*520*920mm |

We offer production lines in various outputs (semi-automatic line or automatic line with an output of 30kg/h, 50kg/h, 80kg/h, 100kg/h, 200kg/h, or higher.). Contact us to tailor one for you. WhatsApp/WeChat: +86 17837195753.

Advantages of Our French Fries Processing Line

- Customizable Solutions: Flexible configuration for different potato sizes, oil types, or packaging needs.

- Easy Operation & Maintenance: Simple controls and durable stainless steel structure guarantee long-term of smooth performance.

- Stable Quality: Every batch of fries maintains uniform size, color, and crispiness.

- High Efficiency: Optimized semi-automatic process ensures faster production with minimal manual labor.

- Cost Efficiency: Reduce labor costs by up to 60% while maintaining consistent quality and reducing waste.

- Scalable Solution: Easily expand your production capacity with modular add-ons as your business grows.

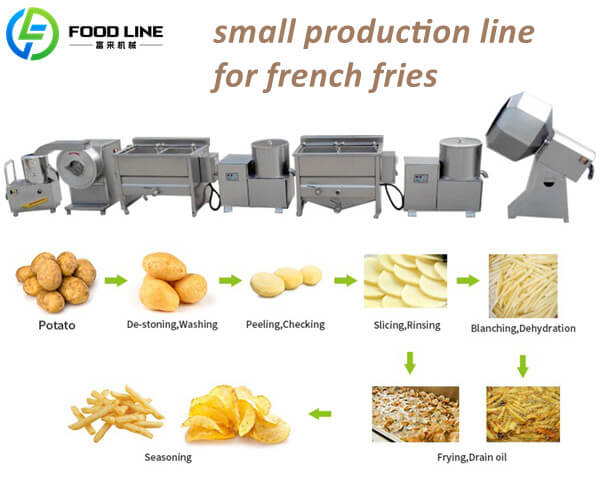

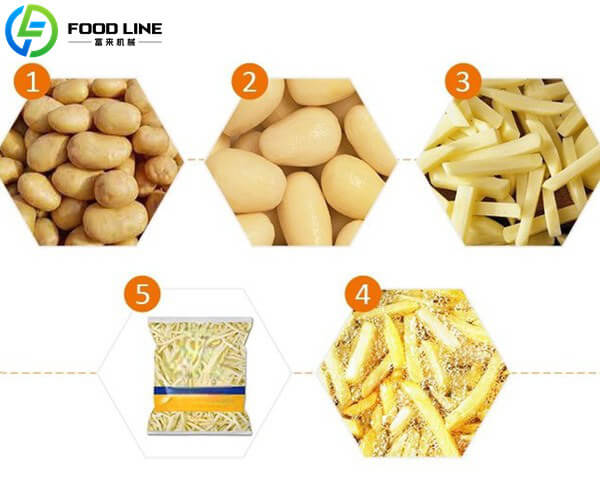

How It Works: Full Production Flow

| Washing & Peeling | Fresh potatoes are thoroughly cleaned and peeled automatically, ensuring a clean surface for cutting. |

| Cutting into Fries | Precision cutting machine slices potatoes into uniform fries, adjustable for different thickness options. |

| Blanching | The fries are pre-cooked in hot water to maintain their texture and avoid discoloration. |

| Dewatering | Excess surface water is removed to prepare fries for even frying and better oil absorption control. |

| Frying | Fries are deep-fried to golden perfection using an energy-efficient fryer with precise temperature control. |

| Deoiling | Centrifugal deoiling removes excess oil, making sure the French fries are crisp, light, and healthier. |

| Seasoning | Fries are evenly coated with flavoring powder or liquid seasoning for your preferred taste profile. |

| Packaging | Automatic packing system seals the fries efficiently, ready for storage or delivery. |

We specialize in customizing our fries lines to match your specific products. Whether you require a frozen french fries production line with integrated french fries freezing equipment or prefer to skip the seasoning section for a natural taste, we can tailor the solution for you. We also offer complete potato chips production line. Contact now for a free quote. Phone/WhatsApp/WeChat: +86 17837195753.

Tailored Solutions Start with Your Free Quote!

Why Choose Foodline Machinery?

Foodline has decades of experience in designing robust and reliable food processing lines.

We provide solution from layout planning and installation to operator training and after-sales support.

We tailor the production line capacity and configuration to fit your specific business needs.

Our equipment complies with international safety and quality standards.

Ready to Grow Your Fry Business? Contact our team today for a free quote. Let Foodline turn your potato supply into a steady stream of profits!

WhatsApp/WeChat: +86 17837195753

Email: admin@foodlineproduct.com