A yogurt making machine line is a complete, integrated industrial system to efficiently transform raw milk into various yogurt products. This includes a series of automated, controlled, and hygienic processes. It ensures consistent product quality, guarantees food safety, extends shelf life, and meets the high-volume demands of yogurt market. Contact us now for a discount! Phone/WhatsApp/WeChat: +86 17837195753

Foodline Yogurt Production Line for Sale

The yogurt making machine line consists of a series of specialized machines and tanks operating in coordination, each playing a specific role in the production process. We develop this line for continuous, large-scale yogurt production, managing the entire process from raw material receiving and processing to fermentation, filling, and packaging the final product. This integration is key to achieving efficient production and maintaining stringent hygiene standards.

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

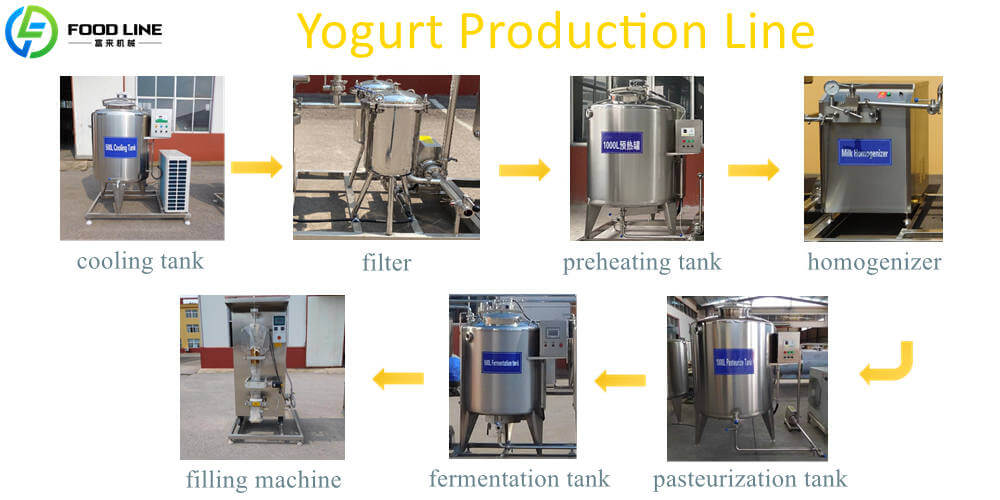

Key Components in Foodline Yogurt Processing Line

1. Cooling Tank – Used for temporary storage and rapid cooling of incoming raw milk.

2. Filter – Uses a double filter or a pipeline filter to remove physical impurities from the milk.

3. Preheating Tank – Heats the milk and standardizes ingredients such as sugars and stabilizers.

4. Homogenizer – Processes the milk under high pressure to achieve a uniform, smooth texture.

5. Pasteurization Tank – Heat-treats the milk to eliminate pathogens and spoilage microorganisms.

6. Fermentation Tank – The core vessel that transforms milk into yogurt by cultivating bacterial cultures.

7. Filling Machine – Packages the finished yogurt into its final sales form, such as cups, bags, or cartons.

8. CIP Cleaning Machine – Automated in-situ cleaning and sanitizing of the entire production line without disassembly, ensuring hygiene and preventing cross-contamination.

Tailored Solutions Start with Your Free Quote!

Yogurt Making Machine Line Tailored to Your Budget

No matter your budget, Foodline offers suitable yogurt production solutions, so that you get the right equipment and avoid overspending or sacrificing quality.

– For startups or small-batch producers with tight budgets, our compact small yogurt making line provides essential functions such as raw material mixing, fermentation, and basic filling. This line effectively reduces unnecessary costs and meets food safety standards. It is ideal for testing market demand or launching your first yogurt product.

– For medium-sized businesses looking to expand, our medium-sized yogurt maker machine line balances efficiency and investment. It features increased automation, faster processing speeds, and the flexibility to produce different flavors of yogurt.

– For large manufacturers or enterprise brands with ample budgets, our high-capacity, fully automated yogurt making machine line maximizes production efficiency. It has advanced quality monitoring systems, continuous production capabilities, and customized packaging integration to to handle large-scale orders.

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Main Process in a Yogurt Manufacturing Line

1. Cooling and storage. Fresh raw milk is immediately cooled to approximately 4°C to maintain its quality.

2. Filtration. The cold milk is passed through a filter to ensure it is free of any solid impurities.

3. Preheating and standardization. The milk is heated to the optimal temperature for homogenization and evenly mixed with other ingredients.

4. Homogenization. The milk is squeezed through a tiny pore to break down fat molecules, prevent oil-water separation, and improve texture.

5. Pasteurization. Through precise time and temperature control, the milk is brought to a level safe for consumption and storage.

6. Fermentation. After cooling to a specific fermentation temperature, bacterial cultures are added. After several hours of fermentation, these cultures give the milk the characteristic texture and rich flavor of yogurt.

7. Filling and Packaging. The finished yogurt is automatically filled into aseptic containers, then sealed and ready for distribution.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Features of Yogurt Production & Filling Line

1. Strict Hygiene and Safety Design

The yogurt making machine line uses food-grade stainless steel. This is a non-porous, corrosion-resistant, and easy-to-clean material. Equipped with a Clean In-Place (CIP) system, the line achieves automated and thorough cleaning without disassembly.

2. Precise Process Control

Key parameters such as temperature (for pasteurization and fermentation), time, pressure (for homogenization), and acidity are precisely monitored and controlled.

3. Modularity and Flexibility

Our line for yogurt production consists of independent functional modules (e.g., pretreatment, fermentation, filling). It can be configured according to different types of yogurt and can be expanded according to different production scales.

4. Superior Product Quality Assurance

The integrated process aims to preserve nutritional value. Homogenization delivers a smooth texture, pasteurization ensures safety, and controlled fermentation promotes flavor development.

Your Free Quote is One Click Away

Frequently Asked Questions | Yogurt Making Machine Line

1. Q: Which languages does the control panel support?

A: English is the standard language. The interface can be customized to other languages free of charge to better serve international users.

2. Q: What are the typical voltage requirements for equipment in the production line for making yogurt?

A: The power requirement for each tank is typically between 1000V and 1500V. We offer solutions such as external transformers or custom motors and heating elements to adapt to the local power grid.

3. Q: How is the yogurt making machine packaged for international shipping?

A: We pack single machines in wooden crates. For complete production lines, we recommend Full Container Load (FCL) shipping. Our team wraps the equipment in protective film, securely places it inside the container, and ties it with straps to prevent damage during transportation. All included at no extra charge.

4. Q: What after-sales support is provided?

A: We offer a one-year comprehensive warranty on all equipment in yogurt making machine line. For malfunctions not caused by human error, we will ship replacement parts free of charge to the designated port in your country.

Click here to get your business started!

Why Choose Foodline for Your Yogurt Production Line?

Foodline has extensive professional experience in the food processing equipment industry and can serve as a reliable partner for you in transforming yogurt production concepts into efficient and reliable practical outcomes. Our core philosophy is to provide tailor-made solutions to meet the needs of various business scales. We offer technical support to ensure that your yogurt making line operates smoothly and drives long-term profit growth.

Are you ready to take the next step in optimizing the yogurt production process? Whether you want to learn about the details of customized services, need a detailed quote, or want to understand how our production line can align with your goals, our team is always available to contact you via text message or phone.

WhatsApp/Tel/WeChat: +86 17837195753

Email: admin@foodlineproduct.com