The steam peeler offers a fast and clean way to peel vegetables and root crops. It uses high-temperature steam and a simple release process. This helps factories get better yield and higher efficiency. Want stable performance and long service life? Foodline industrial steam peeling equipment is a strong choice. Contact for a free quote! Phone/WhatsApp/WeChat: +86 17837195753

Click here to get your business started!

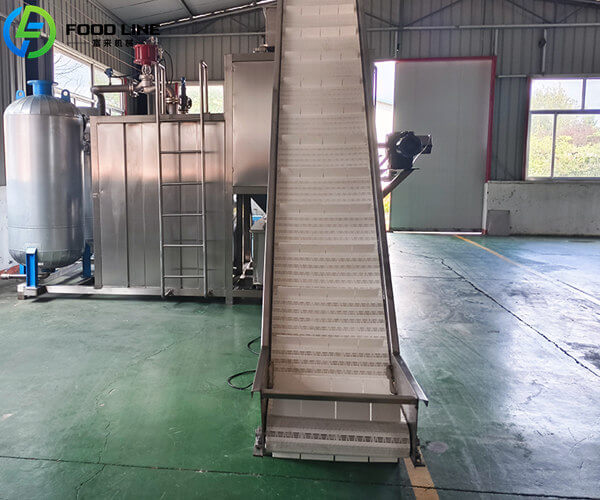

Foodline Steam Peeling Machine for Sale

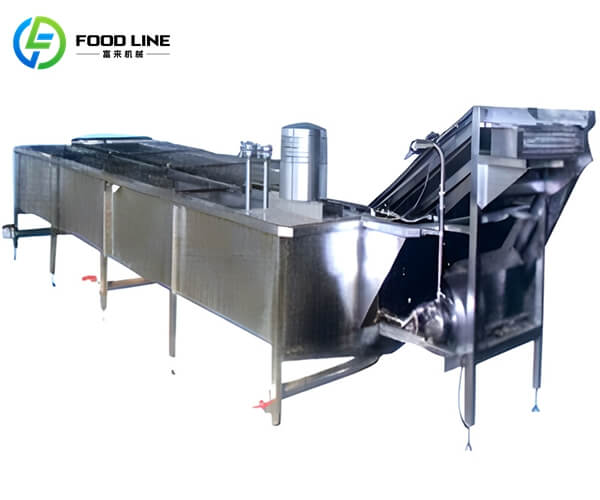

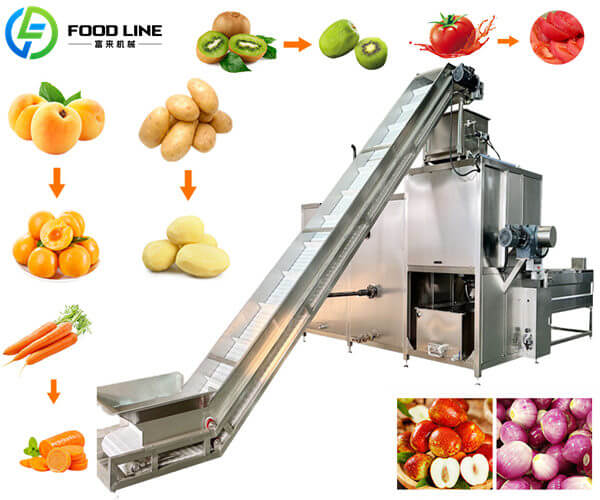

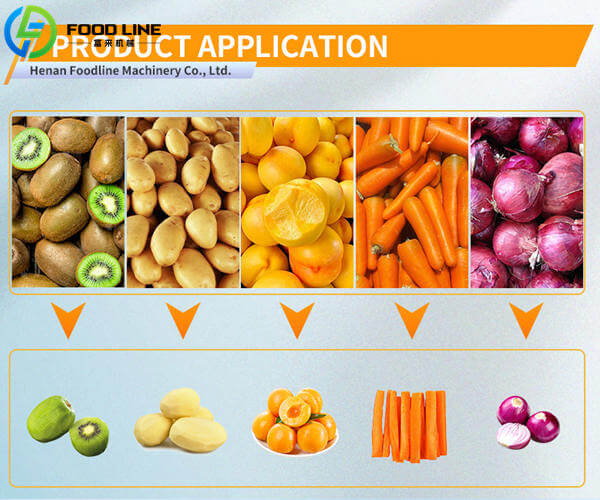

The steam peeler handles many types of raw materials: it works well with potatoes, carrots, beets, sweet potatoes, tomatoes, onions, and other root vegetables. This machine gives you high yield and smooth peeling results. It uses controlled steam pressure and a rapid-release system to remove only the thin outer skin, so you keep more usable product. The structure is stainless steel and easy to clean. The control panel is simple and safe for operators.

Foodline focuses on reliable construction and stable operation. Many processors choose our steam peelers for their operation. Contact us now for a free quote! WhatsApp/Tel/WeChat: +86 17837195753

Technical Information of Industrial Steam Pressure Peeling Machine

| Capacity | 1-3 tons | 3-5 tons |

| Overall Dimensions | 5200*4500*2800mm | 6000*3500*3400mm |

| Rated Total Power | 5kw | 5.65kw |

| Lifting Motor | 1.1kw | 1.1kw |

| Designed Pressure | 12bar | 12bar |

| Operating Steam Pressure | 0.8-1.2Mpa | 0.8-1.2Mpa |

| Steam Consumption | ≤1500kg/h | ≤1500kg/h |

| Required Compressed Air Pressure | 0.8 MPa | 0.8 MPa |

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Key Technical Features of Foodline Automatic Steam Peeler

1. High Efficiency with Minimal Product Loss

Rapid, Uniform Processing. High-pressure steam instantly and evenly envelops the product surface, causing the skin to soften and separate within seconds. This reduces mechanical damage to the flesh compared to abrasive or blade methods.

Higher Yield. Steam peeling preserves more edible material, especially suitable for soft or irregularly shaped fruits and vegetables like tomatoes, peaches, and potatoes.

2. Environmentally Friendly and Safe Operation

Chemical-Free. Utilize only steam and heat, eliminating the need for lye or acid solutions. This avoids chemical residues, and meeting green food processing standards.

Simplified Wastewater Management. Condensed steam wastewater is far less polluting than chemical peeling effluents, reducing environmental treatment costs and complexity.

3. Automation and Process Flexibility

Precision Control. The multi-functional control system can precisely control steam pressure, temperature, and processing time, adapting to different types and sizes of materials.

Production line compatibility. The steam peeler can connect with upstream and downstream equipment, like elevators, washers, brushifiers, etc., to achieve continuous production and improve efficiency.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Application Fields of Steam Peeler for Potatoes and Vegetables

Potato chips and French fry factories

Frozen vegetable plants

Dehydrated vegetable processing

Canned food production

Tomato sauce and paste factories

Central kitchens and catering suppliers

Agricultural product processing centers

If your plant handles large amounts of root vegetables, this steam peeling system for potatoes and vegetables helps you reach stable and high-quality results. Contact us to get your own discount today! WhatsApp/Tel/WeChat: +86 17837195753

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

FAQs

1. How does the steam peeler machine work?

It uses controlled high-temperature steam to soften the skin of fruits and vegetables. This process makes the skin easier to remove; simply brush or spray with water, leaving you with clean, intact produce.

2. What materials can the steam peeling line handle?

It works with potatoes, carrots, beets, tomatoes, onions, sweet potatoes, taro, and other root vegetables.

3. Is this steam peeling machine difficult to operate?

No. Simply put in the ingredients, set the time according to the ingredients, and let the machine work automatically.

4. Can the steam peeling system be added to an existing production line?

Yes. It works well with conveyors, washers, cutters, and packaging equipment.

5. What factors should I consider before purchasing a steam peeler?

Key considerations include required capacity, type of raw materials, peel removal efficiency and yield, energy consumption, etc.

Your Free Quote is One Click Away

Partner With Foodline for Your Peeling Business

Foodline is a trusted leader in R&D, production and sales of food processing equipment, boasting strong technical strength and years of industry experience. Beyond steam peeling machines, we also offer a variety of equipment, including potato washing & peeling machines, onion peelers, garlic peelers and more. We adhere to the philosophy of prioritizing quality, innovation and customer satisfaction, ensuring every machine delivers stable results and long service life.

Contact us today for a free quote, customized solutions or any inquiries. Our team is ready to support your business growth. Reach us via WhatsApp/Tel/WeChat: +86 17837195753!