The meat brine injection machine evenly injects brine into meat, improving its texture, tenderness, and moisture retention. It is crucial in the meat processing industry because it significantly shortens curing time and improves yield. If you are interested, please contact us for a free quote: Phone/WhatsApp/WeChat: +86 17837195753

Foodline Meat Brine Injection Machine for Sale

A meat brine injection machine is able to inject brine, marinades, or other curing solutions directly into meat cuts. The primary purpose is to expedite the marinating process while ensuring uniform distribution of the solution throughout the meat. This method not only reduces the time required for traditional soaking methods but also improves the overall quality of the final product.

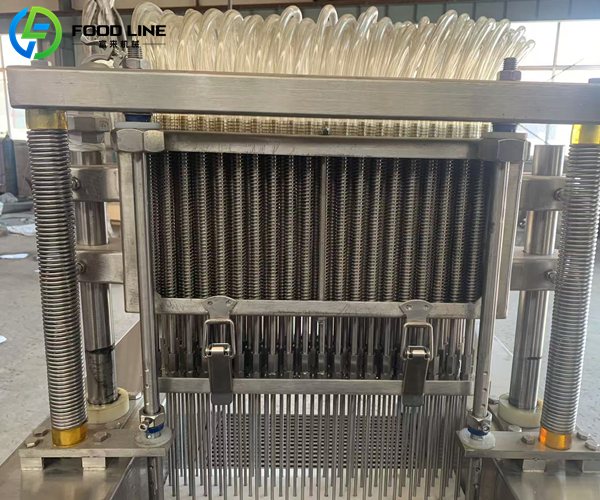

The brine injector machine operates by utilizing a series of needles that penetrate the meat surface and deliver the brine under pressure. The injection process can be precisely controlled, allowing for adjustments in injection depth, pressure, and flow rate. This control ensures that the meat absorbs the brine evenly, leading to enhanced flavor, juiciness, and tenderness.

Technical Parameters of Fresh Meat Saline Brine Injector Injection Machine

| Model | FL-80 | FL-120 |

| Injection Needles | 80 pcs | 120 pcs |

| Production Capacity | 800-1000 kg/h | 500-1500 kg/h |

| Power | 4.15 kw | 1.5 kw (frequency conversion) |

| Trough Width | 400 mm | 420 mm |

| Needle Vertical Stroke | 170 mm | 170 mm |

| Injection Speed | Frequency-conversion speed regulation | Frequency-conversion speed regulation |

| Chain Step Distance | 120 mm | 120 mm |

| Optional Injection Needle Specifications | Ø3 mm, Ø4 mm | Ø3 mm, Ø4 mm |

| Main Machine Dimensions | 1350*1250*1720mm | 1350*1250*1720mm |

| Weight | 500 kg | 550 kg |

Key Features of Automatic Meat Brine Injector

1. High injection precision. The meat brine injector utilizes a toothed step-by-step feeding mechanism with accurate spacing to ensure that every piece of meat receives uniform injection of brine.

2. High adaptability. Operators can fine-tune various parameters such as injection pressure and speed, needle penetration depth, and the distance between injection points based on the size and tissue structure of the object to achieve optimal injection results..

3. Bone-in injection capability. The injection needle is controlled by a gas spring, enabling bone-in injection, minimizing damage to the meat, suitable for a wide range of meat types, including bone-in meat.

4. High level of automation. The fully automatic brine injector enables continuous production, improving efficiency and reducing labor costs.

5. Safe and hygienic. Constructed of stainless steel, our salt water injection machine is easy to clean and disinfect, meeting stringent food safety standards.

Functions of Foodline Meat Saline Brine Injector Machine

1. Injecting marinade. A high-pressure pump delivers marinade to the injection needle, which then evenly injects the liquid as the needle penetrates the meat.

2. Adjustable injection parameters. Adjust the step speed, step distance, gap between the meat press plates, and injection pressure to achieve the desired injection effect based on different process requirements.

3. Automatic protection. If the injection needle strikes a hard object, it will lift and protect it from damage.

Applications of Brine Injection Machine For Meat

1. Commercial Meat Processing. They are widely used in large-scale meat processing plants for producing ham, bacon, sausages, and other cured meats.

2. Poultry Processing. These machines are also employed in the poultry industry for marinating chicken, turkey, and other bird meats.

3. Specialty Meats. They are suitable for processing specialty meats, including game meats and artisanal products where precise control over marination is crucial.

4. Food Service. Smaller machines are used in restaurants and catering businesses to prepare marinated meat dishes efficiently.

Benefits of Automatic Saline Injection Machine for Meat Processing

1. By injecting brine directly into the meat, the marination process is significantly accelerated, reducing overall production time.

2. Uniform brine distribution leads to more consistent flavor, improved moisture retention, and enhanced tenderness, resulting in higher-quality meat products.

3. The injection of brine adds weight to the meat, thereby increasing the yield and profitability of the processed meat.

4. Automated operation reduces the need for manual labor, leading to lower operational costs in the long run.

5. The meat saline injector can handle a wide range of meat cuts and sizes, making them a versatile addition to any meat processing facility.

About Foodline Machinery

Foodline Machinery is a leading manufacturer and supplier of food processing equipment, based in Henan Province, China. Established with a commitment to innovation and quality, the company specializes in designing and producing a wide range of machinery for various food processing applications.

Foodline invests heavily in research and development to stay at the forefront of food processing technology. This commitment to innovation ensures that our products are always up-to-date with the latest industry trends and advancements.