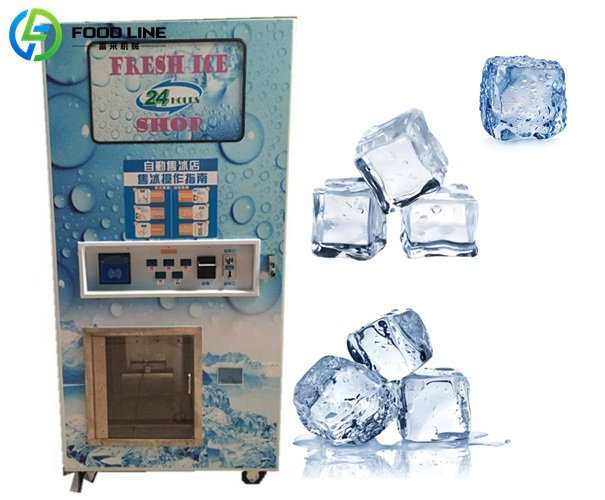

The automatic ice cube vending machine offers a quick and easy way for people to get ice whenever they need it, without the hassle of waiting in lines or relying on traditional stores that may run out of stock. Whether it’s for a family gathering, a road trip, a camping adventure, or a business that requires a steady supply of ice, the automatic ice dispenser is proving to be highly useful. Contact for a free quote: WhatsApp/Tel/WeChat: +86 17837195753.

Specifications of Commercial Ice Vending Machine for Sale

| Machine name | Automatic ice vending machine |

| Voltage | 220/110V |

| Body material | The shell is mad of thickened galvanized sheet, with some parts made of 304 stainless steel. |

| Network link | 4G networking module (full network)/WIFI/Ethernet cable |

| Remote control | Mobile backend control, only requiring one smartphone |

| Standard features | Touch screen, Default card swiping, High speed water ice making module, Automatic ice making, Automatic bagging of ice cubes |

| Optional customization function | Body sticker color, Other payment methods, Other quantities and capacities |

Key Components of Ice Dispensing Machines

An ice cube vending machine is made up of several key components that work together to ensure its proper functioning.

1. The ice-making unit. This is the part that actually creates the ice. It works by spraying water into special molds that are kept very cold by a refrigeration system. The water freezes quickly into ice cubes.

2. The water purification system. It includes a series of filters, and a reverse osmosis membrane. The filters remove sediments, chlorine, bacteria, and other impurities from the water, while the reverse osmosis process further purifies the water by removing dissolved solids.

3. The storage bin. This is the large, insulated container where the ice is kept after it’s made. The insulation helps keep the ice from melting. Sensors in the bin tell the machine when it’s full, so it stops making ice.

4. The vending mechanism. It is responsible for dispensing the ice to the customer. It includes a selection panel where customers can choose between bulk ice or bagged ice and select the quantity.

5. The packaging system. This system only works for bagged ice. It holds the empty bags, moves one into position, opens it up, and then seals it once it’s full of ice. This whole process is automatic to keep things clean and fast.

Features of Self-Service Automatic Ice Vending Machine

1. Robust, All-Weather Construction

Our ice making vending machine adopts a heavy-gauge steel cabinet and a front-opening design. An outdoor-grade, powder-coated finish provides exceptional resistance to rust, corrosion, and UV damage.

2. Uncompromising Hygiene & Safety

All ice and water contact surfaces are constructed from food-grade 304 stainless steel. This material is inherently non-toxic, corrosion-resistant, and easy to clean, guaranteeing the production of pure, safe ice.

3. Advanced Vending & Ice-Making Technology

The ice cube machine employs a stable and efficient vending system to ensure a seamless customer experience, from selection to dispensing. It utilizes an advanced ice mold spray technology to produce crystal-clear, square-cut ice cubes.

4. Fully Automated & Hygienic Packaging

The packaging system operates with complete automation, handling bagging, filling, and sealing without any human touch. This process maximizes hygiene and minimizes the risk of contamination.

Highlights of Foodline Automated Ice Block Vending Machine

1. Flexible Sales Options

To cater to diverse customer needs, the self serve ice machine is capable of dispensing both bulk ice for large events and pre-packaged bags for individual use. This versatility maximizes market appeal and revenue potential.

2. Intelligent, Self-Regulating Operations

The automatic ice vending machine operates autonomously, producing ice to maintain a constant supply. Integrated sensors monitor ice levels, water, and bag inventory, automatically pausing sales to prevent operational errors and ensure customer satisfaction. Remote management is streamlined via a built-in GSM system, which transmits real-time status updates and alerts to owners for proactive maintenance.

3. Premium Water Purification

A state-of-the-art, nine-stage reverse osmosis (RO) water purification system is the foundation of our ice quality. This multi-stage filtration process removes all impurities, chemicals, and contaminants, producing water that meets drinking water standards and results in exceptionally pure, great-tasting ice.

We Are a Real Factory

Foodline equips its factory with state-of-the-art manufacturing facilities and advanced production lines. We have a team of experienced engineers, designers, and technicians who work diligently to create high-quality automatic ice vending machine. And our machines have sold to Germany, Italy and other countries. From the initial design phase to the final assembly, every step is carefully monitored to ensure that the machines meet our strict quality standards.

Foodline has a strict quality control process in place. Every machine that leaves our factory undergoes rigorous testing to ensure that it functions properly, meets all safety and performance standards, and is ready for immediate use. If you would like to know more about our vending machines, get in touch with us now! We welcome your inquiry! Phone/WhatsApp/WeChat: +86 17837195753