For businesses that need to freeze food products efficiently, the high efficiency industrial spiral freezer provided by Foodline can help you. It uses a vertical spiral belt to freeze items quickly within a small footprint, ensuring excellent quality preservation for everything from meats to vegetables. For more details or to discuss your specific needs, please reach out to us via Phone, WhatsApp, or WeChat at +86 17837195753.

Foodline Spiral Freezer for Quick Frozen Foods

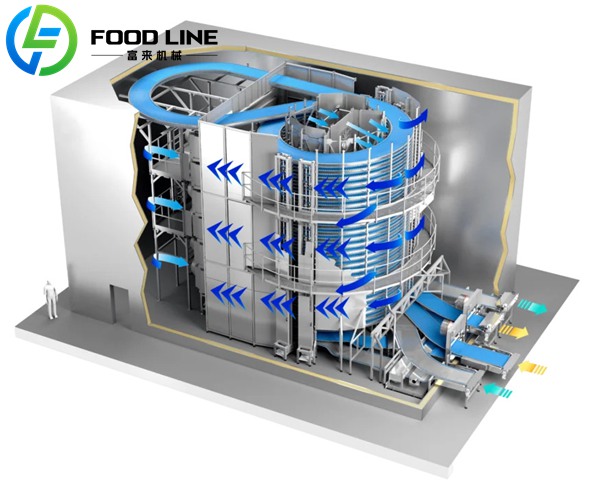

Our spiral-type freezer is an efficient continuous freezing system to handle a high throughput of products. Instead of using a long, straight conveyor belt that requires a vast amount of floor space, the spiral freezing machine cleverly winds its conveyor belt into a vertical spiral. This compact tower-like structure allows products to travel a long freezing path within a confined area. As items move through this spiral pathway, a controlled, intense stream of cold air circulates around them, rapidly extracting heat. This approach is ideal for various products, including individual quick-frozen (IQF) fruits and vegetables, ready-made meals, and baked goods.

Free Quote Now! Phone/WhatsApp/WeChat: +86 17837195753

Technical Highlights of Efficient Spiral Freezers

Production line speed and conveyor tier spacing can be adjusted to handle various products, from delicate shrimp to large poultry, with consistent efficiency.

Horizontal airflow systems use adjustable stainless-steel fans to create a uniform cold air “curtain,” ensuring even freezing without weak spots. Optimized belts and airflow openings enhance consistency.

Constructed from high-grade stainless steel and food-safe plastics, spiral freezer machine prioritizes easy cleaning with smooth surfaces and minimal areas for dirt accumulation.

Compatible with multiple refrigeration systems, including fluorinated gases, ammonia, carbon dioxide, or chilled brine. Defrosting options, like hot gas or electric heaters, minimize downtime.

Our spiral cooler has a simple, menu-driven touchscreen interface and supports remote monitoring and maintenance, streamlining operation and troubleshooting.

Tailored Solutions Start with Your Free Quote!

Specifications of Foodline Spiral Blast Freezer

| Model | FL-SF200 | FL-SF300 | FL-SF500 |

| Output Capacity | 200kg/h | 300kg/h | 500kg/h |

| Inlet Temperature | +15°C | +15°C | +15°C |

| Outlet Temperature | -18°C | -18°C | -18°C |

| Inner Temperature | -38±3°C | -38±3°C | -38±3°C |

| Retention Time | Adjustable | Adjustable | Adjustable |

| Belt Material | Food grade stainless steel | Food grade stainless steel | Food grade stainless steel |

| Cabinet Dimension | 4000mm*3300mm*2100mm L*W*H | 4900mm*4050mm*2500mm L*W*H | 5600mm*4000mm*2900mm L*W*H |

| Length of Inlet/Outlet Device | 1000mm / 500mm | 1000mm / 500mm | 1000mm / 500mm |

| Height of Inlet/Outlet Device | 800mm / 1925mm | 800mm / 2060mm | 800mm / 2620mm |

| Evaporating Area | 360 square meters | 540 square meters | 900 square meters |

Instant Quote! Phone/WhatsApp/WeChat: +86 17837195753

Various Application Areas

Foodline industrial spiral freezer is hard at work across countless food processing sectors, delivering reliable performance in a variety of applications:

The meat and poultry industry relies on the freezer to efficiently freeze products ranging from burger patties and chicken nuggets to sausages and whole birds.

Seafood processing operations benefit from its ability to handle individually quick-freezing (IQF) of shrimp, scallops, fish fillets, and fish sticks.

Prepared foods and ready meals producers use spiral freezing machines to achieve consistent results with items like pizzas, pasta dishes, sandwiches, and microwaveable dinners.

Bakery and pastry production facilities depend on the freezing equipment to freeze bread, rolls, cakes, and pastries, effectively locking in freshness.

The fruit and vegetable sector employs spiral freezers for IQF applications, perfectly preserving the quality of peas, corn, berries, and carrot dices.

Your Free Quote is One Click Away

Identifying the Ideal Investor Profile of Spiral Freezer Systems

1. Growing food manufacturers – Companies that are scaling up their production and need a freezing solution that can keep up with increasing volume.

2. Quality-conscious processors – Businesses whose brand reputation relies on delivering high-quality frozen products with excellent texture and taste.

3. Space-constrained facilities – Operations that need high-capacity freezing but lack the extensive floor space required for tunnel freezers.

4. Processors of diverse product lines – Companies that need a flexible freezing solution capable of handling a wide variety of product shapes and sizes with quick changeovers.

Free Quote! WhatsApp/Tel/WeChat: +86 17837195753

Frequently Asked Questions (FAQs)

1. How time-consuming is the cleaning process for a spiral belt freezer?

With its smooth, non-porous materials and cleaning-friendly design, cleaning is quick and efficient, whether using cleaning-in-place systems or manual access.

2. Can fragile products be frozen without damage?

Yes, the gentle belt motion and even air distribution ensure delicate items like pastries, fish fillets, or soft fruits are preserved without harm.

3. Is a spiral freezer energy-intensive to operate?

No, it is designed for energy efficiency with high-density insulation, efficient fans, and advanced refrigeration cycles to reduce electricity use and operating costs.

Click here to get your business started!

Why Buy from Foodline?

Foodline specializes in the research, development, and manufacturing of advanced food processing equipment. With years of technical expertise and a deep understanding of industry challenges, we provide tailored solutions that enhance productivity and product quality. Our commitment extends beyond delivery—we offer comprehensive technical support and collaborative partnership to ensure your long-term success.

Contact us today to discuss how we can support your production goals: Phone / WhatsApp / WeChat: +86 17837195753.