Foodline is pleased to announce the recent sale of our advanced meat brine injector to a Mexican food processing company. For inquiries about this equipment or customized quotes, reach out to our team directly. Phone/WhatsApp/WeChat: +86 17837195753

Technical Parameters of Commercial Meat Brine Injector

| Model | FL-80 | FL-120 |

| Injection Needles | 80 pcs | 120 pcs |

| Production Capacity | 800-1000 kg/h | 500-1500 kg/h |

| Power | 4.15 kw | 1.5 kw (frequency conversion) |

| Trough Width | 400 mm | 420 mm |

| Needle Vertical Stroke | 170 mm | 170 mm |

| Injection Speed | Frequency-conversion speed regulation | Frequency-conversion speed regulation |

| Chain Step Distance | 120 mm | 120 mm |

| Optional Injection Needle Specifications | Ø3 mm, Ø4 mm | Ø3 mm, Ø4 mm |

| Main Machine Dimensions | 1350*1250*1720mm | 1350*1250*1720mm |

| Weight | 500 kg | 550 kg |

Mexican Client Purchased a Brine Injection Machine

The client, a meat processor based in Monterrey, Mexico, supplies marinated products to retail chains and restaurants across Northern Mexico. Facing rising demand for consistent flavor distribution and faster production cycles, he sought equipment to replace their outdated manual injection system.

Key Challenges Faced by the Client

- Inconsistent product quality. Manual injection led to uneven brine distribution, affecting taste and shelf life.

- Labor-intensive processes. High reliance on skilled workers slowed output and increased costs.

- Scalability issues. Existing systems couldn’t adapt to fluctuating order volumes without significant downtime.

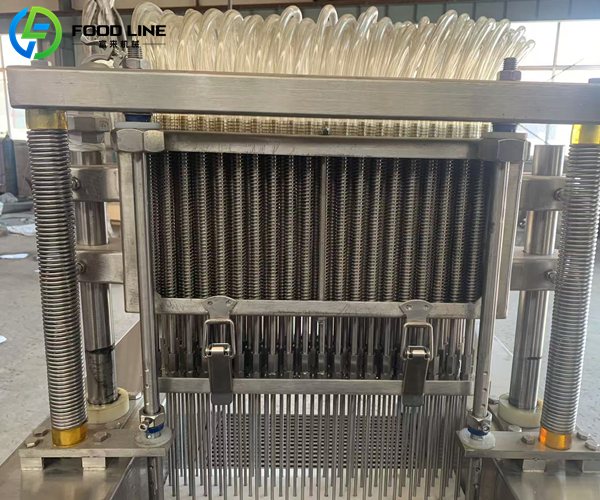

Foodline’s Solution – Automatic Meat Brine Injector Machine

After evaluating the client’s workflow, Foodline recommended our automatic meat brine injection machine for precision and adaptability. Key features addressed his pain points:

- Multi-zone pressure control. Ensures uniform brine penetration across varying meat densities, reducing waste from over/under-injection.

- Modular design. Allows quick reconfiguration for different cuts (e.g., poultry, pork) or batch sizes, cutting changeover time by 40%.

- Integrated cleaning system. Automates sanitation between batches, complying with Mexico’s stringent food safety standards.

Impact on the Client’s Operations

Since installing the Foodline brine injection machine for meat, the client has seen significant improvements in their production process.

Increased Efficiency

The injector’s high-speed operation has reduced the time needed for marinating, allowing the client to meet growing demand without compromising quality. This has also helped them optimize labor costs, as fewer workers are needed to manage the process.

Improved Product Quality

By ensuring consistent brine distribution, the meat brine injector has enhanced the flavor and texture of the final products. This has led to higher customer satisfaction and repeat orders, boosting the client’s reputation in the market.

Reduced Waste

The precise injection system minimizes over-injection, which can lead to product spoilage. As a result, the client has reported a noticeable decrease in waste, contributing to cost savings and sustainability goals.

Scalability

The saline injection machine’s modular design allows the client to scale up production as needed. Whether they’re processing small batches or large orders, the auto brine injector adapts seamlessly to his requirements.

Why Meat Brine Injector Matters for Client’s Business

The Mexican market exemplifies broader trends in food manufacturing: tighter margins, stricter regulations, and consumer demand for premium products. Foodline’s meat injector machine tackles these challenges through:

- Precision engineering. Consistent results minimize costly errors.

- Future-proof design. Scalable configurations adapt to market shifts.

- Localized support. On-call technicians and regional spare parts ensure minimal downtime.

For processors in Latin America and beyond, investing in smart automation isn’t optional—it’s a competitive necessity.

Why Choose Foodline

Foodline has built a reputation for delivering reliable, high-performance equipment tailored to the unique needs of the food processing industry. Our brine injectors are engineered to enhance productivity, ensure product consistency, and comply with global safety standards. With a team of experienced professionals, we provide comprehensive support, from installation to after-sales service, ensuring our clients get the most out of their investment.

Get Your Customized Quote Today

Foodline’s brine injection systems are built to meet your unique production goals. Whether you’re upgrading existing lines or launching a new facility, our team will work with you to:

- Analyze your workflow

- Recommend optimal configurations

- Provide transparent pricing

Contact us for a no-obligation proposal: Phone/WhatsApp/WeChat: +86 17837195753; Email: admin@foodlineproduct.com